Uncovering Solutions: The Power of the 5 Whys in Problem-Solving

Introduction

In the intricate dance of problem-solving, the ability to ask the right questions often determines the quality of the solutions obtained. One powerful and elementary approach to problem-solving is the “5 Whys” technique, a method that encourages deep thinking through persistent questioning. Originally developed by Sakichi Toyota within the Toyota Motor Corporation, this technique has proven its efficacy in swiftly identifying the root causes of problems. In this article, we will delve into the mechanics of the 5 Whys and explore its application in real-life problem-solving scenarios.

The 5 Whys Strategy

The 5 Whys strategy is a systematic approach to problem-solving that involves asking “Why?” repeatedly until the root cause of a problem is uncovered. The process starts by identifying the specific problem and then iteratively asking why the problem occurred, drilling down to its fundamental cause. This approach is not only simple but also highly adaptable, making it applicable to a wide range of issues.

How to Conduct 5 Whys Analysis

- Define the Problem: Begin by clearly articulating the problem at hand. Writing it down helps formalize the issue and ensures that the entire team is focused on the same problem.

- Ask “Why”: Ask why the problem occurred and record the answer. If the answer does not pinpoint the root cause, proceed to the next step.

- Repeat: Continue asking “Why?” for each answer obtained, creating a chain of causation. Repeat this process until the team reaches a consensus on the root cause.

- Develop Corrective Actions: Once the root cause is identified, develop appropriate corrective actions to eliminate the issue from the system.

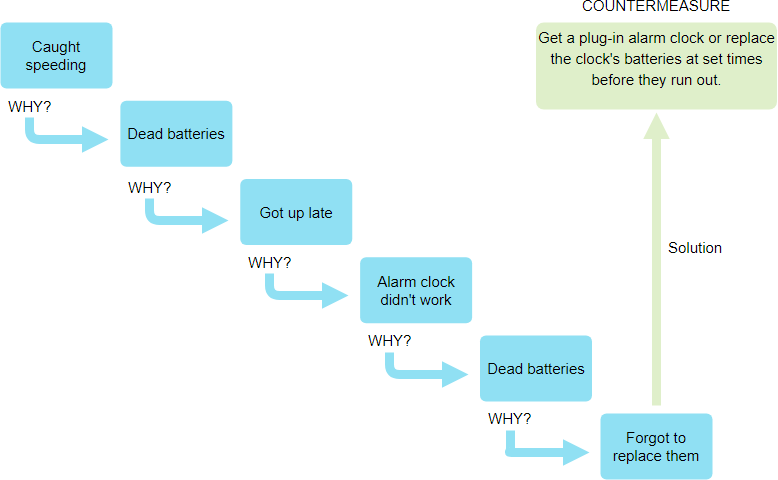

Example of 5 Whys in Action

Let’s take a practical example of a vehicle not starting:

- The vehicle will not start (The problem)

- Why? – The battery is dead (First why)

- Why? – The alternator is not functioning (Second why)

- Why? – The alternator belt has broken (Third why)

- Why? – The alternator belt was well beyond its useful service life and not replaced (Fourth why)

- Why? – The vehicle was not maintained according to the recommended service schedule (Fifth why, a root cause)

Note: The process could extend to a sixth or seventh “Why,” but five iterations are generally sufficient to identify the root cause.

Criticisms of the 5 Whys

While the 5 Whys technique is a valuable tool, it is not without criticisms. Some of the notable critiques include:

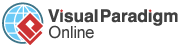

- Stopping at Symptoms, Not the Root Cause: Critics argue that the technique might lead investigators to address symptoms rather than digging deep into the actual root cause.

- Limited by the Investigator’s Knowledge: The effectiveness of the analysis relies on the knowledge and experience of the investigator, potentially limiting the scope of the investigation.

- Not Asking the Right Why Questions: The success of the technique depends on asking the right questions, and if these are not framed appropriately, it may yield inaccurate results.

- Not Repeatable – Different People Build Different 5 Whys: Different investigators may develop different 5 Whys analyses for the same problem, leading to inconsistencies.

- The Tendency to Isolate a Single Root Cause: Critics argue that the technique might oversimplify complex problems by isolating a single root cause, ignoring potential systemic issues.

Conclusion

Despite its criticisms, the 5 Whys technique remains a valuable tool in the arsenal of problem-solving methodologies. When applied conscientiously and collaboratively, it enables teams to unearth the underlying causes of problems and implement effective corrective actions.

Embracing the simplicity of asking “Why?” multiple times can lead to profound insights, fostering a culture of continuous improvement and innovation in problem-solving.